The Liviri Vino blueprint, from test lab to real-world results

Wine shipping is experiencing a flood of activity. According to the latest report from SOVOS and Wines Vines Analytics, US consumers spent $3 billion on direct-to-consumer (DTC) wine shipments in 2018 alone.

During the same year, wineries shipped more than 6 million cases, posting a 9% increase in total volume shipped.

Wine buying behavior in this growing DTC channel is a story of seasons. Peak wine country visits — in summer and fall — drive increases in wine shipments during the same months. But weather is the wrinkle, as most wineries avoid shipping during the hottest and coldest temperatures of summer and winter.

“You end up having all these orders that are bought and paid for, packaged and sitting in temp-controlled warehouses, waiting for the right moment to be safely shipped,” says Alan Morine, Liviri Vino product development lead. “Oftentimes these businesses are watching the weather… and just waiting for the right window to send wine in standard packaging.”

A MOBILE WINE CELLAR IN THE MAKING

Liviri Vino was envisioned and designed to overcome seasonal shipping holds. It brings to life a portfolio of high-performing, thermal wine shippers designed for safe, cost-effective ground transportation. By eliminating weather holds and allowing year-round deliveries, your consumers get the wine they want, when they want it, while your operations run smoothly and consistently.

Since the entire container is reusable, it’s also a sustainable solution that eliminates single-use styrofoam, corrugate and ice packs, while its easy return-shipping label process and premium presentation and display combine to heighten the experience for wine lovers.

Over the past two years, the team at Otter Products leveraged its more than 20 years of injection molding expertise into innovating the ultimate wine shipper. With Liviri Vino, “we are able to tap into insulation core competencies developed from our OtterBox Venture cooler,” Morine says. “You add that to our injection molding and design background, and you have a great formula — the right tools and the right people — for creating a product that helps solve problems for the wine industry.”

At the root of the problem rests the run-of-the mill carboard box — standard packaging that, by design, hinders the four-season flow of wine. Even with EPS inserts added, corrugate boxes aren’t great insulators. And all this leads to fine wines sitting idle for weeks on end, because if shipped in corrugate the wine gets too hot, it “cooks” and loses its intended magic. The same goes for wine when it gets too cold.

Experts agree that ideal temperatures for aging fine wine is 45 to 65 degrees F. — a temperature range that you’ll find in wine cellars. Information published by Purdue University dives deeper into the temperature debate and suggests that wine can handle even more hot or cold, without incurring damage, so long as it’s for short periods of time. Purdue concludes that temperatures from 65 to 80 degrees, during a 1- to 3-week window, are safe for wine either at rest or on the move.

The challenge for the Liviri team was taking that profile and incorporating it into a mobile box that may encounter wide temperature swings along its journey.

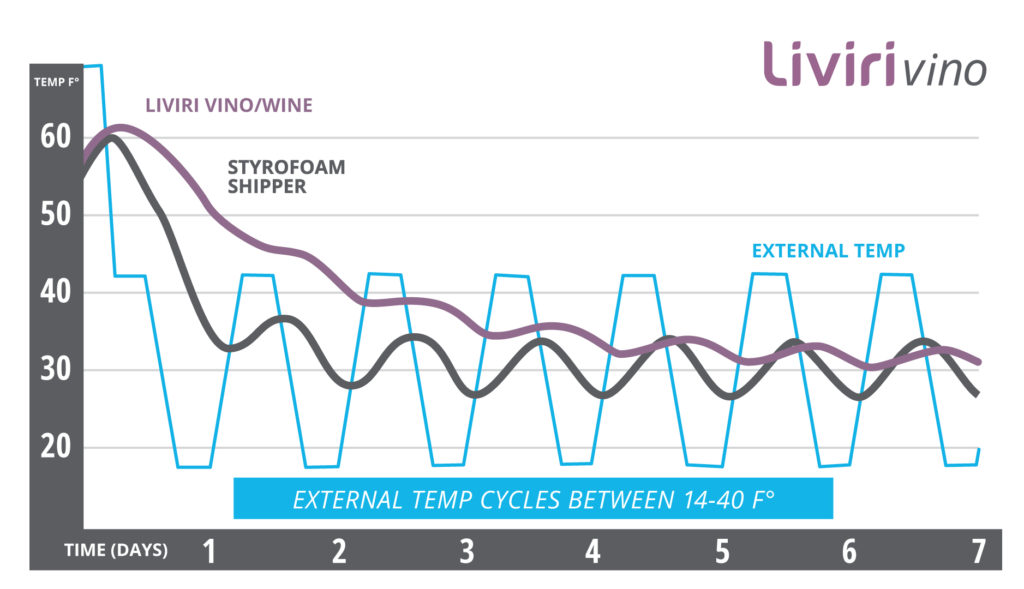

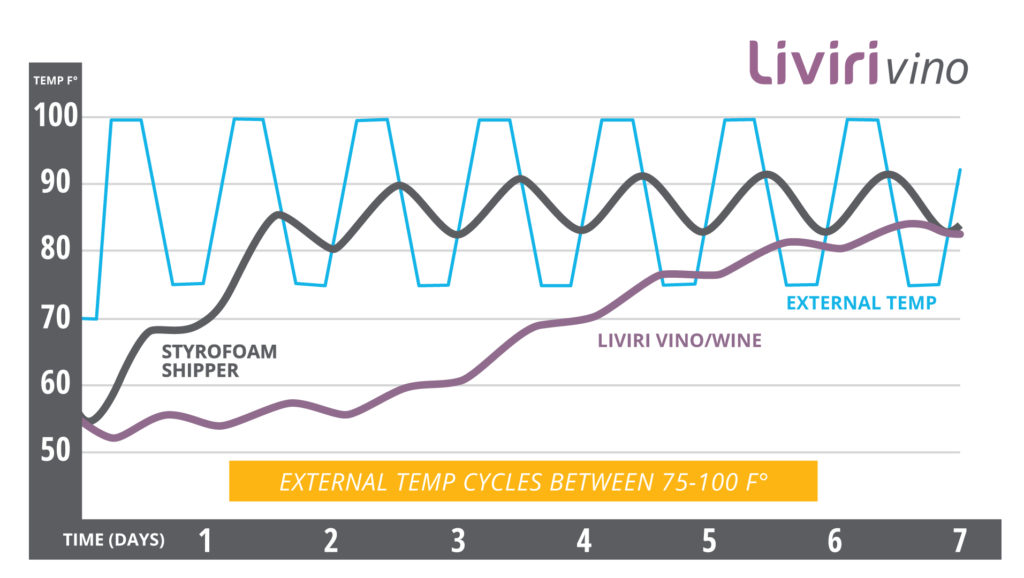

Enter the “PIT Lab” — essentially a boot camp for boxes set up by Otter Products to test the fitness of wine shipping prototypes. In the wine and beverage industry you won’t find many predefined standards for boxes. The International Safe Transit Association has certain protocols, “but when we evaluated those, we didn’t feel they were aggressive enough, so we established our own temperature profile to better represent ground shipping scenarios during summer shipping, 75 to 100 degrees,” Morine says.

“We then vetted these temperature profiles for summer and winter with the customers we’re working with. That gave us the ability to standardize on exactly how and what we were going to test.”

Engineers used environmental chambers to study thermal performance. These climate chambers were programmed to cycle through daily highs and lows. Box prototypes, test mules, were then loaded with wine bottles and ice packs and monitored over the course of 5 to 7 days — simulating ground shipping legs for moving wine from West Coast to East Coast.

From the lab to real world shipping routes, Liviri Vino boxes are now touring the country, with wine, of course, but also with temperature monitoring technology inside to validate performance.

“To see the data and temperature profiles, and to see the box perform — that’ been one of the most exciting things for me,” says Liviri Industrial Designer Grady Barfoot. “We’ve shipped to Texas and Florida during months when wine typically doesn’t make it beyond the safety of a cool cellar, and it’s temperature stays right where it should be. That’s been great validation.”

CRAVE-WORTHY WINE SHIPPING MADE EASY

With a solid technical solution in hand, the next step was ensuring that Liviri Vino is a good all-around fit for customers. Does it work with a distributor’s pack-out operations? And will it sync with consumers’ wants and needs, in terms of their overall experience unpacking wine, returning the box for reuse and limiting waste.

“People and businesses generally dislike dealing with styrofoam packaging, and they don’t enjoy handling wet, sloppy ice packs,” Barfoot says. The issues with styrofoam (expanded polystyrene) are twofold: 1) it’s difficult to recycle, and 2) it’s incredibly brittle. “If you wanted to make a reusable anything, you wouldn’t select styrofoam because it breaks too easily,” he continues. “Plus, wineries and distribution centers we’ve visited tell us they hate it. Not only that, their consumers hate it.”

In blueprinting Liviri Vino, Otter Products found a better performing, less wasteful alternative in the form of expanded polypropylene. EPP provides ample cushioning for fragile bottles. It’s also a lightweight, capable insulator — and, due to its high durability, it works great for reuse.

“So that’s where we landed with the box designs. We wanted wine shoppers to be able to open Liviri Vino with a certain degree of wow factor. Like, ‘This is a great presentation, my wine is perfect and I don’t have to deal with a bunch of styrofoam waste,’ Barfoot says. “Ultimately, this is a very technical box, but there’s a premium presentation and experience at work as well.”

With Liviri Vino, the deluxe experience is a product of thoughtful details — inside and out. Quick-clip latches make opening the box a breeze, and reusable ice packs aren’t handled by the consumer, so the wine takes center stage. When it comes to removing bottles, the included tote makes for simple transfers. People who receive wine at work, for instance, or pick up orders at a FedEx location, can now simply leave the box behind (a return shipping label is included) and use the tote to carry their assorted bottles home.

GREAT PAIRINGS: VINO4 & VINO6

The Liviri Vino portfolio includes two upstanding options: Vino4 and Vino6. The main differences are revealed in the names. Vino4 houses four bottles that ride horizontally, with labels facing up, while Vino6 increases wine capacity to a half-dozen bottles that ride standing tall, in the center of the container.

Beyond differences in volume, each box also has its own unique highlights. “Given all our learnings from Vino4, we had a head start on Vino6,” Morine says. “We explored at least a dozen configurations of the wine bottles and ice packs. This gave us the ability to pinpoint exactly how much ice was needed to keep the wine cold during that 5- to 7-day shipping window.”

The biggest challenge in creating Vino6 was matching the superior thermal performance of its 4-bottle brother, without adding a lot of extra weight. By engineering a more efficient configuration inside the container, the design team optimized coolant load for a light, agile shipper. “The key was keeping the bottle-to-bottle temperature difference to only a couple degrees,” Barfoot explains. “When we figured out the magic ratio it was an exciting moment — like we created the perfect box.”

The vertical orientation of the bottles was a key part of that perfection-making process. “Some customers prefer the wines to be standing, because it makes packing easier,” Morine says. “The box is lighter, smaller and the wine is still in temperature. The design of the 6-bottle container also looks really cool. It makes you think, ‘Hey, this box is meant to do something really great.’”

Versatile performance underscores that greatness. And whether you’re choosing Vino4 for your wine club or selecting Vino6 to ship more volume safely and efficiently, the Liviri Vino portfolio offers high-performance solutions that complement a DTC wine shipping channel that continues to uncork new opportunities.